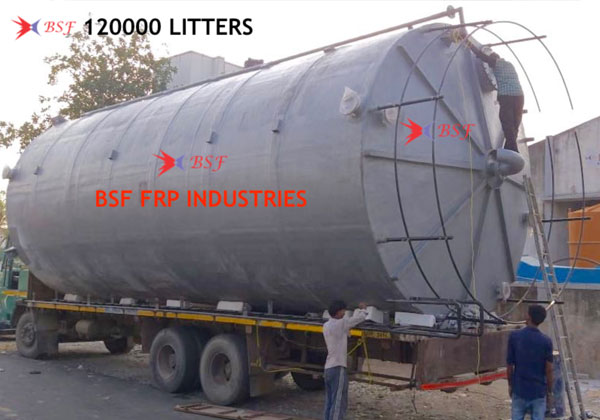

FRP storage tank is specially designed to store wide range of chemical and liquids in industrial applications. BS Projects is a leading FRP storage tank (FRP Chemical Storage Tank) manufacturers in Mumbai, India. Our broad range of FRP Storage tanks can be used for chemical Storage, oil Storage, water Storage, liquid Storage and many other applications. We manufacture horizontal and vertical FRP tank as per customer requirements.

There are various types of FRP Storage Tanks available that are known for their strength, reliability, durability, Storage capacities, cost effective and convertible. If you are looking for, FRP Storage Tanks you are at right place.We will assist you to find best and suitable Storage Tanks for your business.

| Product Details : | |

|---|---|

| Tank Material | FRP (Fibre-reinforced plastic) |

| Storage Capacity | Upto 250 KL (in – house), 250 – 500 KL (at site) |

| Country Of Origin | Made in India |

| Storage material | Chemical, Oil, Water, Other Liquid |

FRP tanks are mostly used in various industries because of their durability, corrosion resistance and versatility.

Tanks & Vessels can be made in the following materials of construction FRP using various grades of resin like thermoplastic, Isophthalic (Polyester), Vinyl Ester, Bisphenol, Super Vinyl Ester (Epoxy Novolac based).

PP+FRP, PVC+FRP, PVDF+FRP, CPVC+FRP, FEP+FRP, PFA+FRP, ECTFE+FRP etc.